Failure analysis under plane strain

Head

Researcher

Funding period:

Start: 1. April 2022

Ende: 31. March 2024

Abstract

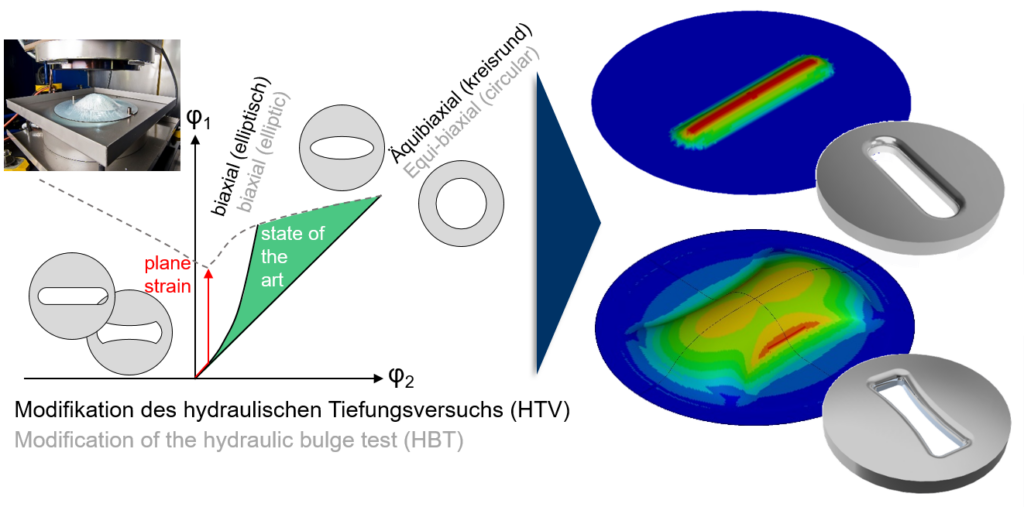

The challenge of this research project is the exact design of products made of sheet metal materials. In common practice, components manufactured in this way are nowadays designed by means of numerical simulations. This type of design is significantly influenced by the quality of the input parameters, such as the characteristic values from the material characterization. The assumption of wrong input parameters can predict a component failure too late or a component failure too early. For this very reason, large safety factors are often included in practical applications, leading to a conservative design with only moderate utilization of the material's limits. However, an improvement in the utilization of the material's potential is significantly influenced by an exact material characterization. In particular, the area of plane strain, which is often the cause of failure in deep-drawing or stretch-forming components, must be investigated and improved. Conventional characterization tests under plane strain can show nonlinearities in the strain path or are friction-induced or strongly affected by assumptions due to their test setup. Thus, the objective of this research project is to improve the characterization under plane strain for an improved failure prediction in order to shift the process limits to higher forming ratios and higher achievable drawing depths. The conventional characterization of forming limit change is to be improved to better predict failure under plane strain in order to increase the quality of input parameters for component design.