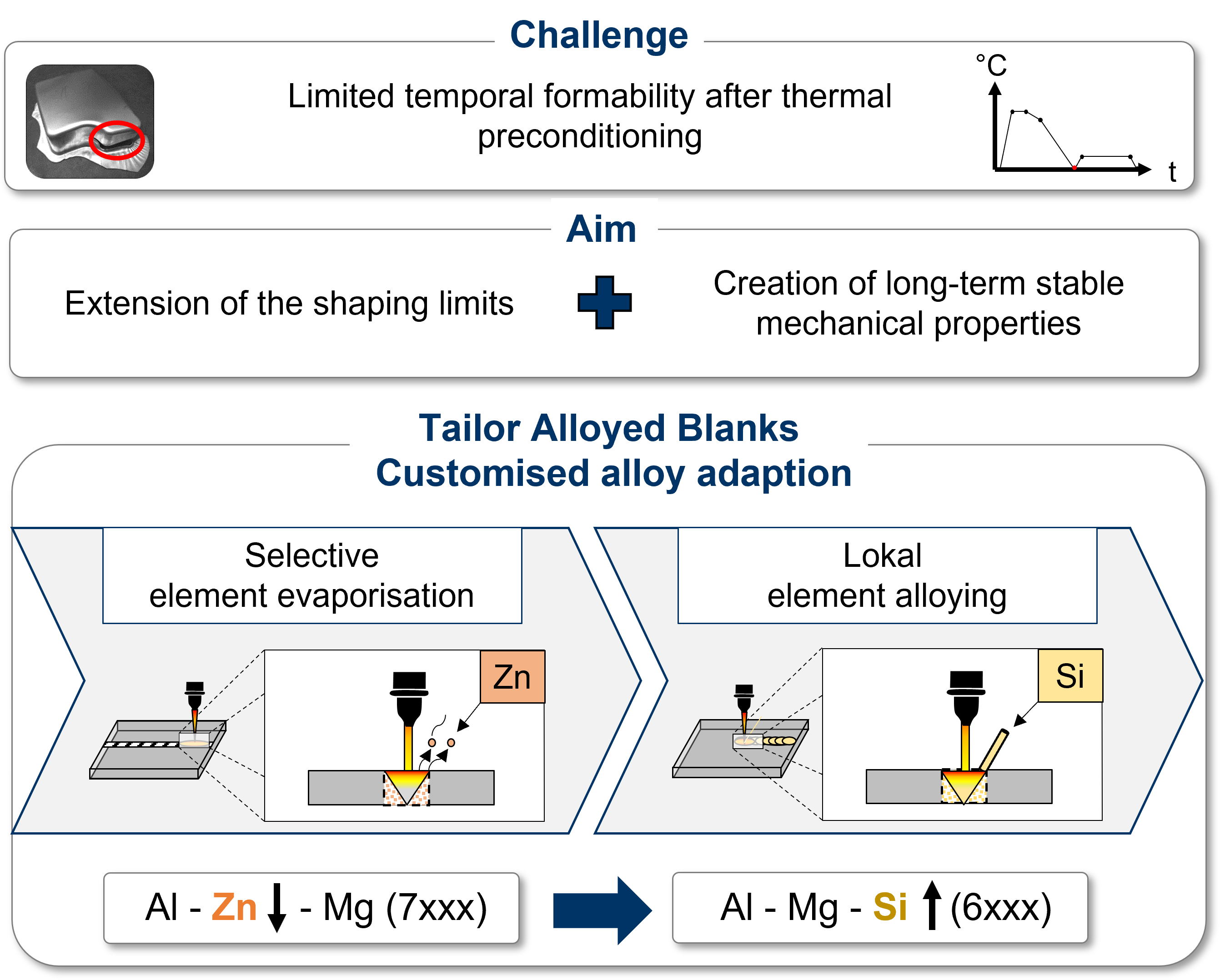

Tailor Alloyed Blanks - Manufacturing of high-strength process-adapted semi-finished parts by a local laser-based adaption of the alloying system

Head

Researcher

Funding period:

Start: 1. January 2024

Ende: 31. December 2025

Abstract

The aim of the proposed research project is the extension of the forming limits and the defined adjustment of the mechanical properties of high-strength aluminum alloys by a tailored local adaption of the alloying system prior to forming. In order to improve the elastic-plastic properties of high-strength 7xxx aluminum alloys, metallurgical as well as methods of laser material processing are used to perform a local microstructure modification over the entire depth of the semi-finished product. Targeted concentration reduction through element evaporation and the addition of alloying elements should allow a local adaptation of the chemical composition towards 6xxx aluminum alloys, since this alloy class exhibits higher forming limits. Since primarily the high zinc content in combination with magnesium in alloys of the 7000 series leads to a lower forming capacity than grades with lower strength, it is necessary to locally reduce the concentration of these elements and to replace them, if necessary, with other alloying elements. Specifically, this requires magnesium and zinc evaporation as well as silicon input in order to avoid a critical silicon concentration of 0.8% by weight, which promotes hot cracking. In addition, a minimum magnesium concentration should be sought to reduce the strength. This can be attributed to the decreasing number of vacancies, which have a high binding energy to magnesium atoms, and thus favor the transformation. This represents a significant innovation to the current state of research, which has actually been limited to the extension of the design limits of high-strength aluminum alloys by means of warm-forming or hot-forming processes or a local heat treatment. The prerequisite for a successful local adaption of the alloying system is the fundamental scientific determination of interactions in the element evaporation of low-boiling alloying elements in combination with the insertion of additional elements, as well as the influence of laser material processing on the resulting mechanical properties. Furthermore, the reworking of the alloy zone as well as the diffusion behavior of the introduced alloying elements form the further focal points of the research project. On the basis of a characterization of the resulting mechanical properties, the simulative design of a forming process ultimately takes place in order to verify the methodology on the basis of a demonstrator component.

Research groups

Publications

2025

- , , , , , :

Local adaptation of aluminum blanks through laser de-alloying and wire alloying

21st International Conference on Sheet Metals (Paderborn, 1. April 2025 - 3. April 2025)

In: SheMet2025 2025

DOI: 10.21741/9781644903551-45 - , , , :

Improving the local formability of a AA7075 aluminum alloy by laser-induced modification of the alloying concept

In: MATEC Web of Conferences 408 (2025), p. 01018

ISSN: 2261-236X

DOI: 10.1051/matecconf/202540801018