Optische Dehnratenregelung in der Werkstoffcharakterisierung

Head

Researcher

Funding period:

Start: 1. February 2023

Ende: 31. January 2025

Verlängert: 31. July 2025

Abstract

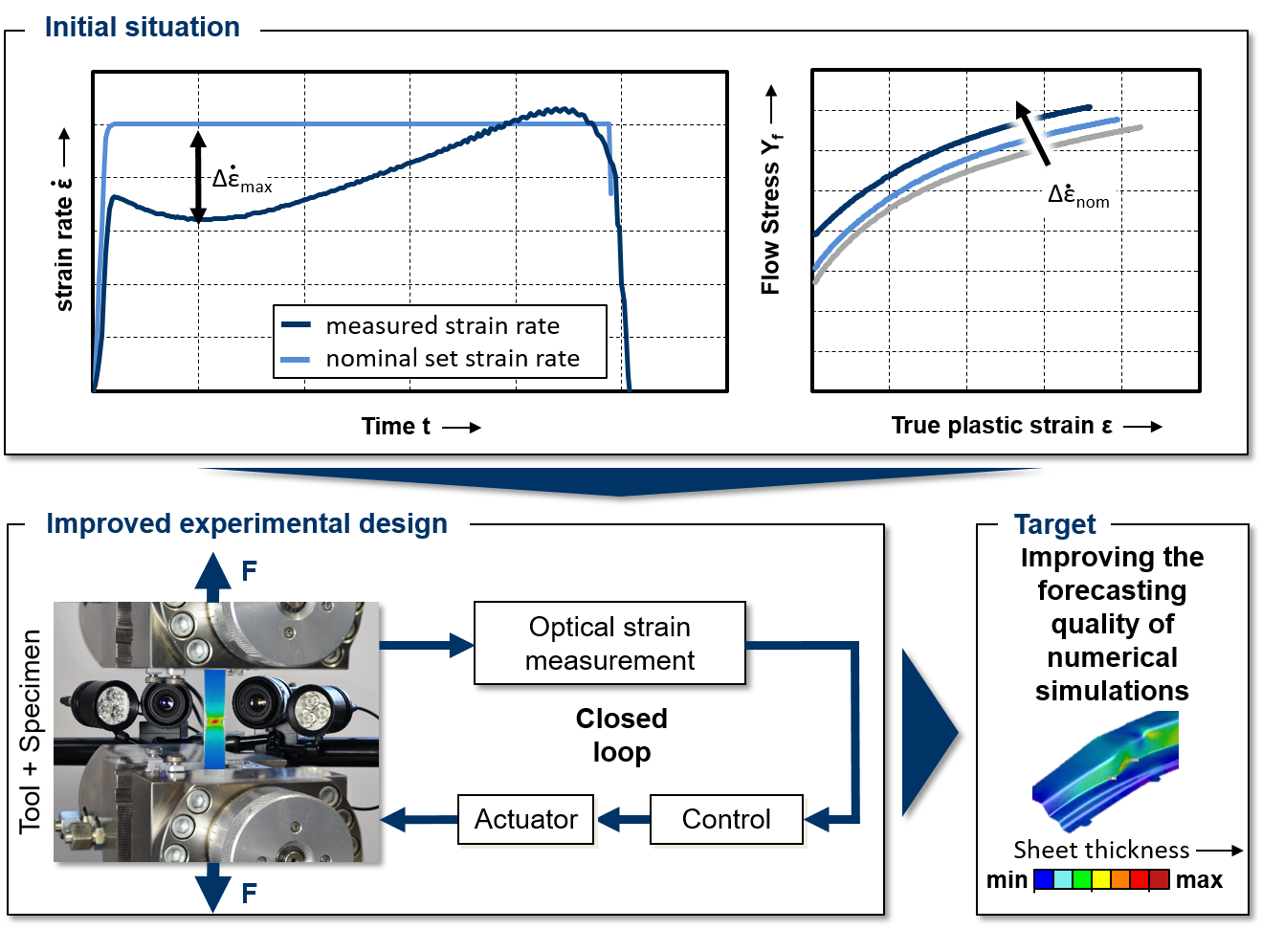

By improving the accuracy with which material behavior is represented in simulations, components and manufacturing processes can be designed more resourceefficiently. Thus, material characterization plays a central role in the implementation of new lightweight design strategies and the achievement of better vehicle crash behavior.

A fundamental knowledge of material behavior is necessary for the targeted forming of metallic materials. Characterization tests, such as the tensile test, are used to determine specific material parameters such as yield stress, tensile strength, uniform elongation and elongation at break. In addition, the elastic-plastic material behavior can be analyzed. Through the appropriate choice of a material model, this material behavior is mapped in a simulation. Formingsimulations represent the manufacturing process and are used for the design of tools and sheets and contribute to the safe and resource-saving design of parts.

Most metallic materials exhibit strain rate sensitivity. This means that the material behavior changes depending on the forming speed. In particular, quasi-static characterization tests carried out at low strain rates, which hardly ever occur in real forming processes, lead to deviations from the real material behavior. Thus, the consideration of the actual strain rate sensitivity leads to an improved material modeling and thus simulative representation of the material behavior.

The aim of the research project is therefore to develop, in cooperation with the project partners, a robust method for carrying out optically strain-rate-controlled tests and to analyze the influence on the prediction quality of simulations. This will reduce the difference between the nominally selected strain rate and the actual strain rate. By this method, more accurate material parameters are measured, which in turn enables an improved component and process design.

Research groups

Publications

2025

- , :

Tensile testing of sheet metals at elevated temperatures with optical strain rate control

44th Conference of the International Deep Drawing Research Group (IDDRG 2025) (Lissabon, 1. June 2025 - 5. June 2025)

In: 44th Conference of the International Deep Drawing Research Group (IDDRG 2025) 2025

DOI: 10.1051/matecconf/202540801002 - , , , :

Forming limit determination of sheet metals at constant true strain rates

The 13th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes (München, 7. July 2025 - 11. July 2025)

DOI: 10.1088/1742-6596/3104/1/012006

2024

- , :

Influence of an optical strain rate controlled tensile testing method on mechanical properties of sheet metals

The 27th International ESAFORM Conference -On Material Forming (Toulouse, 24. April 2024 - 26. April 2024)

In: Material Forming The 27th International ESAFORM Conference -On Material Forming 2024

DOI: 10.21741/9781644903131-101 - , :

Impact of optical strain rate controlling on the determination of mechanical sheet metal properties

6th MATFEM Conference (Hohenkammer, 13. May 2024 - 14. May 2024)