Workpiece-side Impact on the Tribological Conditions within Hot Stamping

Head

Researcher

Funding period:

Start: 1. November 2019

Ende: 31. October 2021

Abstract

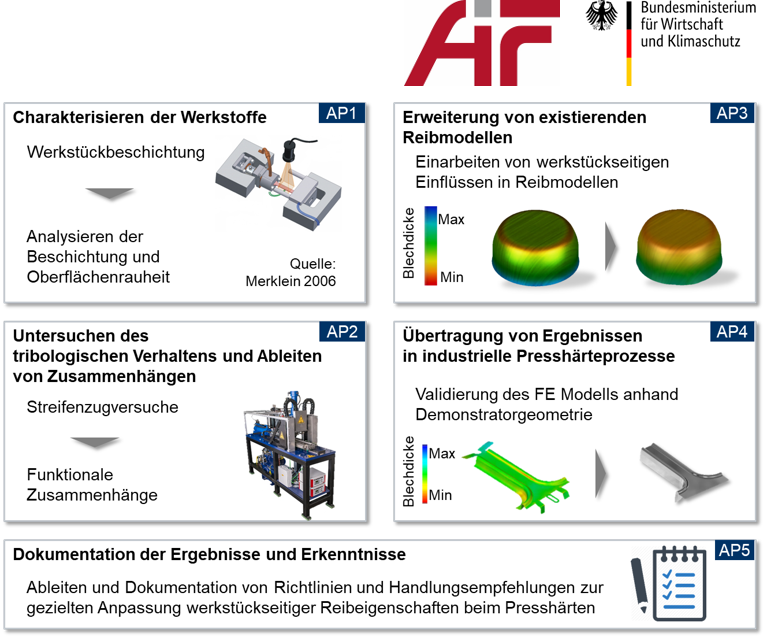

Hot stamping has been established in

the automotive industry for the production of ultra-high-strength

components. Since the use of lubricants has so far not been possible due

to the high operating temperatures > 850 °C, high friction

coefficients coupled with wear occur in the process. In the project

P1291/IGF 20339 N "Workpiece-side influence of tribological conditions

during hot stamping", funded by the FOSTA, AiF and BMWK, the influence

of workpiece-side austenitization parameters and material coatings as

well as the resulting tribological application behavior was determined

against this background. The influence of different heating parameters

and coatings on layer formation and friction behavior was investigated

in the strip drawing test. The significant influencing parameters and

interactions were then incorporated into a friction model for realistic

numerical representation of the friction behavior and validated on the

basis of real experiments. The results and findings in the project were

summarized in a final report, which will soon be available from FOSTA.

Six publications were produced as part of the project. Student theses

involved in the project were awarded and supported by the Dörrenberg

StudienAWARD, the Stiftung Industrieforschung scholarship, and the DIEHL

Master Prize.

Funded by Federal Ministry of Economics and Climate Protection based on a resolution of the German Bundestag.

Research groups

Publications

2022

- , :

Investigation of the impact of process parameters on the layer formation of AlSi coated boron-manganese steel

International Deep-Drawing Research Group Conference (IDDRG 2022) (Lorient, 6. June 2022 - 10. June 2022)

DOI: 10.1088/1757-899X/1238/1/012010 - , :

Werkstückseitige Beeinflussung und Modellierung der tribologischen Bedingungen beim Presshärten

2022

(Forschung in der Praxis, Vol.P 1291)

ISBN: 978-3-96780-147-7 - , :

Investigation of the impact of the layer formation of AlSi coated boron-manganese steel in regard to friction and wear

International Conference on Hot Sheet Metal Forming of High Performance Steel (Barcelona, 30. May 2022 - 2. June 2022) - , , :

Entwicklung von Ansätzen zur Erweiterung der Prozessgrenzen in industrienahen Laborversuchen anhand einer Streifenzuganlage

17. Workshop Warmblechumformung (Fürth, 15. November 2022 - 15. November 2022)

In: Marion Merklein (ed.): Warmumformung von höchstfesten Vergütungsstählen: Tagungsband zum 17. Erlanger Workshop Warmblechumformung, Erlangen: 2022

2021

- , :

Untersuchung des Einflusses von werkstückseitigen Parametern auf die Schichtausbildung von zinkbeschichtetem Bor-Manganstahl

16. Workshop Warmblechumformung (Fürth, 9. November 2021 - 9. November 2021)

In: Marion Merklein (ed.): Warmumformung von höchstfesten Vergütungsstählen: Tagungsband zum 16. Erlanger Workshop Warmblechumformung, Erlangen: 2021 - , :

Investigation of the impact of heat treatment on the layer formation of AlSi-coated boron-manganese steel

40th International Deep-Drawing Research Group Conference (IDDRG)

In: INTERNATIONAL DEEP-DRAWING RESEARCH GROUP CONFERENCE (IDDRG 2021), BRISTOL: 2021

DOI: 10.1088/1757-899X/1157/1/012009