Mechanical joining of dissimilar materials by shear clinching processes without pre-punching (shear clinching)

Head

Researcher

Funding period:

Start: 1. February 2013

Ende: 31. August 2019

Abstract

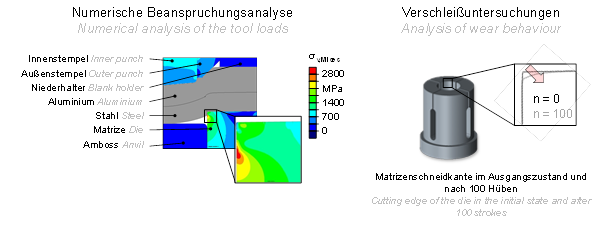

Shear-clinching is an innovative technology for joining by forming of dissimilar materials without additional fasteners. A form and force fitting joint is created by the indirect cutting of the die-sided sheet material with low ductility and the lateral extrusion of the punch-sided material. The objective of the research, which is conducted in cooperation with the LWF in Paderborn, is the further development of the technology. Since the shearing of the die-sided sheet and the extrusion of the punch-sided material both lead to high process forces, the tool loads during shear-clinching and the wear behaviour of the active tool elements are analysed within the third phase of the project, which is part of the priority program 1640. This enables the design of tools with low wear and the improvement of the process stability.

Research groups

Publications

2021

- , :

Potential of shear-clinching technology for joining of three sheets

In: Journal of Advanced Joining Processes 3 (2021), p. 100043

ISSN: 2666-3309

DOI: 10.1016/j.jajp.2021.100043

2020

- , , :

Influence of the properties of the joining partners on the load-bearing capacity of shear-clinched joints

In: Journal of Materials Processing Technology 283 (2020), Article No.: 116696

ISSN: 0924-0136

DOI: 10.1016/j.jmatprotec.2020.116696 - , :

Influence of tool wear on the load-bearing capacity of shear-clinched joints

In: Defect and Diffusion Forum 404 DDF (2020), p. 3-10

ISSN: 1012-0386

DOI: 10.4028/www.scientific.net/DDF.404.3

2019

- , , , :

Application of Tailor Heat Treated Blanks technology in a joining by forming process

In: Journal of Materials Processing Technology 264 (2019), p. 259-272

ISSN: 0924-0136

DOI: 10.1016/j.jmatprotec.2018.09.006 - , , , :

Geometric and corrosive influences on load-bearing capacity of multi-element shear-clinching specimen

22nd International ESAFORM Conference on Material Forming, ESAFORM 2019 (Vitoria-Gasteiz, 8. May 2019 - 10. May 2019)

In: Pedro Arrazola, Eneko Saenz de Argandona, Nagore Otegi, Joseba Mendiguren, Mikel Saez de Buruaga, Aitor Madariaga, Lander Galdos (ed.): AIP Conference Proceedings 2019

DOI: 10.1063/1.5112565 - , , :

Influence of the Material Combination on the Load-bearing Capacity of Shear-clinched Joints

1st International Conference on Advanced Joining Processes AJP 2019 (Ponta Delgada, São Miguel, 24. October 2019 - 25. October 2019) - , , , :

Investigation of the tool wear behaviour in shear-clinching processes during the running-in phase

22nd International ESAFORM Conference on Material Forming, ESAFORM 2019 (Vitoria-Gasteiz, 8. May 2019 - 10. May 2019)

In: Pedro Arrazola, Eneko Saenz de Argandona, Nagore Otegi, Joseba Mendiguren, Mikel Saez de Buruaga, Aitor Madariaga, Lander Galdos (ed.): AIP Conference Proceedings 2019

DOI: 10.1063/1.5112569 - , , , :

Untersuchung der Werkzeugbeanspruchung und des Verschleißes beim Schneidclinchen

In: Lehrstuhl für Umformtechnik, Montanuniversität Leoben, Martin Stockinger (ed.): XXXVIII. Verformungskundliches Kolloquium 2019 - , , , , , :

Fundamental mechanisms and their interactions in shear‐clinching technology and investigation of the process robustness

In: Materialwissenschaft und Werkstofftechnik (2019)

ISSN: 0933-5137

DOI: 10.1002/mawe.201900030

2018

- , , , , , :

Shear-Clinching of Multi-Element Specimens of Aluminium Alloy and Ultra-High-Strength Steel

In: Key Engineering Materials 767 (2018), p. 389-396

ISSN: 1013-9826

DOI: 10.4028/www.scientific.net/KEM.767.389 - , , , , :

Investigation of the influence of tool-sided parameters on deformation and occurring tool loads in shear-clinching processes

In: Procedia Manufacturing 15 (2018), p. 1346-1353

ISSN: 2351-9789

DOI: 10.1016/j.promfg.2018.07.349 - , , , , , , :

Numerical Investigation of the Tool Load in Joining by Forming of Dissimilar Materials Using Shear-Clinching Technology

In: Key Engineering Materials 767 (2018), p. 397-404

ISSN: 1013-9826

DOI: 10.4028/www.scientific.net/KEM.767.397