Development of a self-learning transformation and dilatometer model for the virtual process design of hot stamping processes

Head

Researcher

Funding period:

Start: 1. July 2019

Ende: 30. September 2021

Abstract

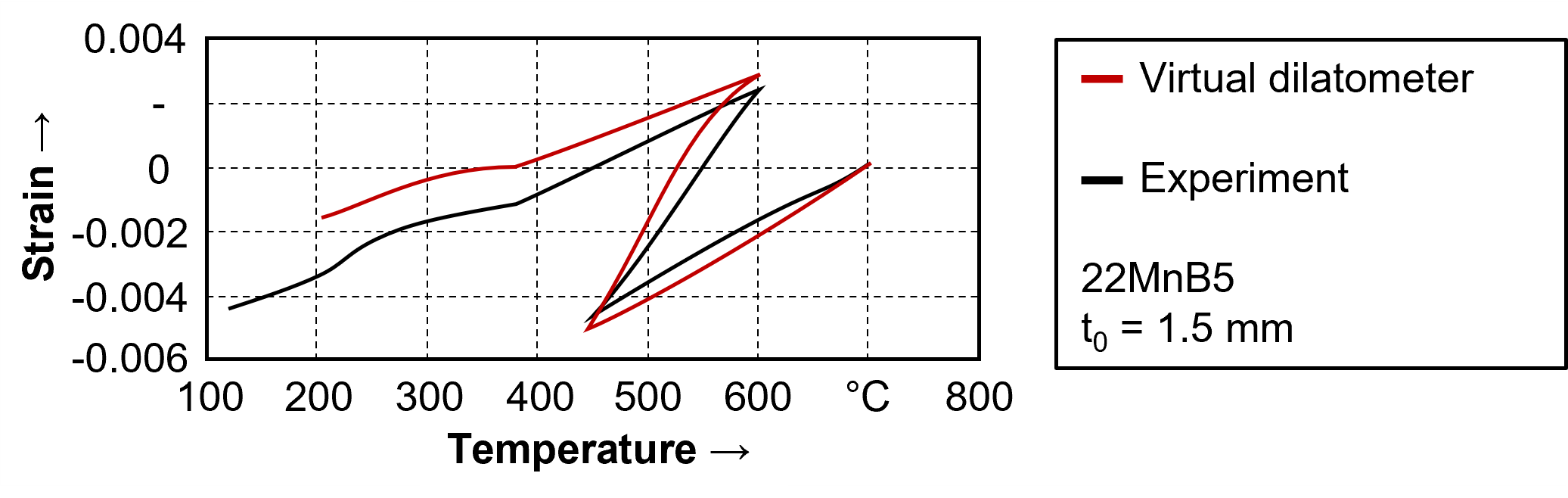

Partial hot stamping is a process

variant to conventional hot stamping for manufacturing parts with

tailored properties. In terms of a time and cost-efficient process

design, an accurate prediction of the microstructural changes over the

process chain is necessary. To minimize the experimental effort for

this, a virtual dilatometer was developed within the framework of this

research project. Therefore, an extensive database was set up. Based on

the experimental data, an existing material model was extended. Together

with a self-learning function for iterative experimental design, this

is the main part of the virtual dilatometer. The developed process model

was validated through a hot stamped demonstrator component.

Research groups

Publications

2020

- , , , , :

Investigation of the Phase Transformation in Hot Stamping Processes with Regard to the Testing Facility

Congress of the German Academic Association for Production Technology WGP 2021 (Dresden, 28. September 2021 - 1. October 2021)

DOI: 10.1007/978-3-662-62138-7_8