Laser implantation of press hardening tools to influence the tribological and thermal properties for the process application

Head

Researcher

Funding period:

Start: 1. July 2018

Ende: 30. June 2020

Verlängerung: 31. August 2020

Abstract

Key development goals of the automotive industry are to increase the passenger safety as well as to reduce the fuel consumption and to observe emission regulations. The lightweight concept of body-in-white parts enables the realization of these goals and sets new standards in terms of functionality and aesthetics. Hence, hot stamping has been established as a suitable and resource efficient process to manufacture high-strength components.

This method combines the hot forming and quenching of semi-finished parts in one process step. The high ultimate tensile strength of the components is caused by a transformation of an austenitic into a martensite structure. Due to the high process temperatures the hot stamping tools are exposed to high thermo-mechanical stresses. In addition, the workpiece out of 22MnB5 is coated with an AlSi layer to protect the surface against oxidation and decarburization. As a side effect, this coating system leads to an increased adhesive wear on the tool surface. A time and cost consuming rework of the hot stamping tool is required. The use of lubricant is not possible at elevated temperatures.

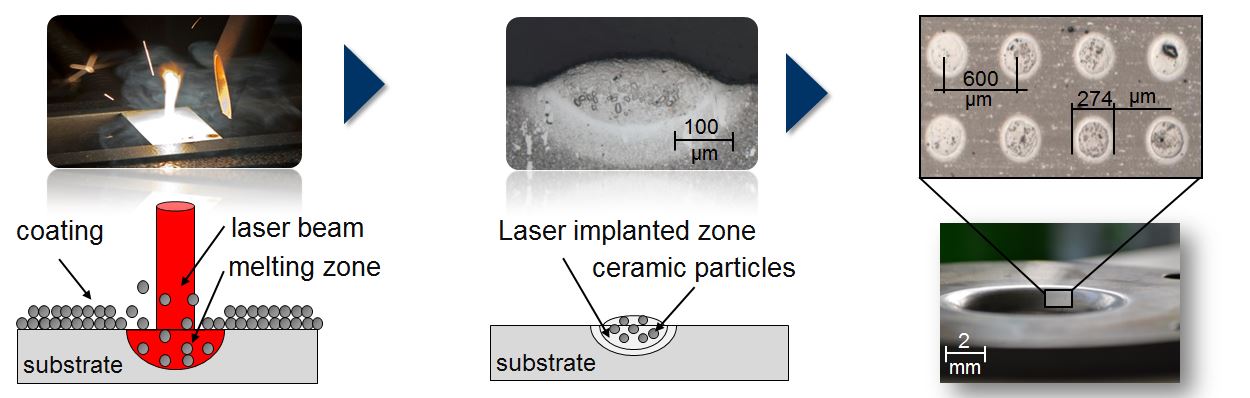

The overall aim of this research project is to increase the wear resistance of hot stamping tools. Therefore a laser implantation process is realized in cooperation with the Federal Institute for Materials Research and Testing. In highly stressed areas ceramic hard materials are dispersed into the substrate material in deterministic patterns using a pulsed laser beam. The wear, friction and cooling behavior of the modified tool surfaces are analyzed before and after the tribological stress. With this knowledge specific guidelines for industrial applications can be deduced.

Schematic representation of the laser implantation process

Source: [Federal Institute for Materials Research and Testing.]

Research groups

Publications

2022

- , , , :

Tribological and thermal behavior of laser implanted tool surfaces for hot stamping AlSi coated 22MnB5 sheets

In: Defect and Diffusion Forum 414 (2022), p. 69-74

ISSN: 1012-0386

DOI: 10.4028/p-e4i60t

2020

- , , , :

Laser implantation of niobium and titanium-based particles on hot working tool surfaces for improving the tribological performance within hot stamping

The A-coatings (Lehrstuhl für Fertigungstechnologie, Friedrich-Alexander-Universität Erlangen-Nürnberg, 16. November 2020 - 20. November 2020)

In: Defect and Diffusion Forum 2020

DOI: 10.4028/www.scientific.net/DDF.404.117 - , , , :

Verbesserung des tribologischen Einsatzverhaltens von Presshärtewerkzeugen durch Laserimplantation titanbasierter Hartstoffpartikel

15. Erlanger Workshop Warmblechumformung (Neue Materialien Fürth GmbH, 90762 Fürth, Deutschland, 17. November 2020 - 17. November 2020)

In: Marion Merklein (ed.): 15. Erlanger Workshop Warmblechumformung 2020 - , , , :

Localized Laser Dispersing of Titanium-Based Particles for Improving the Tribological Performance of Hot Stamping Tools

In: Journal of Manufacturing and Materials Processing 4 (2020), Article No.: 4030068

ISSN: 2504-4494

DOI: 10.3390/jmmp4030068 - , , , :

Localized dispersing of TiB2 and TiN particles via pulsed laser radiation for improving the tribological performance of hot stamping tools

11th CIRP Conference on Photonic Technologies, LANE 2020 (, 7. September 2020 - 10. September 2020)

In: M. Schmidt, F. Vollertsen, E. Govekar (ed.): Procedia CIRP 2020

DOI: 10.1016/j.procir.2020.09.069 - , , , , :

On the influence of TiB2, TiC, and TiN hard particles on the microstructure of localized laser dispersed AISI D2 tool steel surfaces

In: Journal of Laser Applications 32 (2020)

ISSN: 1042-346X

DOI: 10.2351/7.0000059

2019

- , , , :

Untersuchung des tribologischen Einsatzverhaltens von lokal dispergierten Presshärtewerkzeugoberflächen

14. Erlanger Workshop Warmblechumformung (Neue Materialien Fürth GmbH, 90762 Fürth, 19. November 2019 - 19. November 2019)

In: M. Merklein (ed.): 14. Erlanger Workshop Warmblechumformung 2019 - , , , :

Tribological performance of localized dispersed X38CrMoV5-3 surfaces for hot stamping of Al-Si coated 22MnB5 sheets

7th International Conference Hot Sheet Metal Forming of High-Performance Steel (Luleå, 2. June 2019 - 5. June 2019)

In: Oldenburg M, Hardell J, Casellas D (ed.): Hot Sheet Metal Forming of High-Performance Steel CHS² 2019 - , , , , :

Investigations on TaC Localized Dispersed X38CrMoV5-3 Surfaces with Regard to the Manufacturing of Wear Resistant Protruded Surface Textures

In: Lasers in Manufacturing and Materials Processing (2019)

ISSN: 2196-7229

DOI: 10.1007/s40516-019-00106-x - , , , , , :

Microstructural evolution and geometrical properties of TiB2 metal matrix composite protrusions on hot work tool steel surfaces manufactured by laser implantation

In: International Journal of Advanced Manufacturing Technology (2019)

ISSN: 0268-3768

DOI: 10.1007/s00170-019-04630-0