Manufacturing of tailored aluminum parts by controlling the local cooling rates in a combined forming, quenching and hardening process (Tailor Quenched Forming)

Head

Researcher

Funding period:

Start: 1. January 2022

Ende: 31. December 2023

Abstract

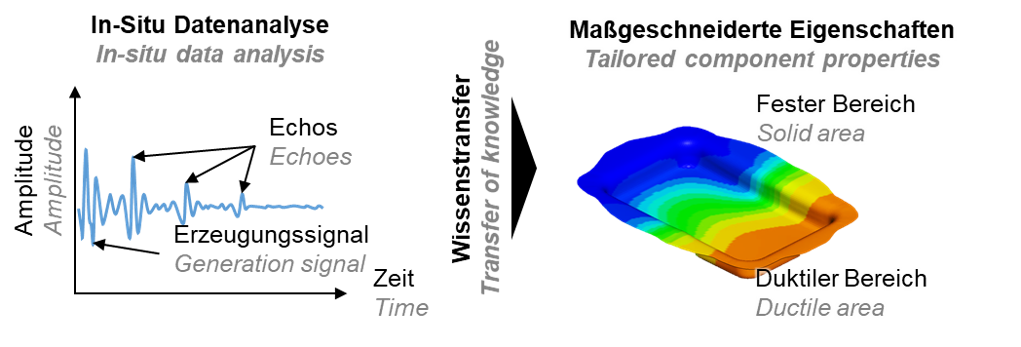

A common method for increasing passenger safety in vehicles is the use of high strength materials for structural safety-relevant parts. Due to the targeted adjustment of the mechanical properties, tailored components can be manufactured with locally adapted component strengths. In case of a crash, they have the ability to absorb or transfer the occurring energy to other regions of the vehicle. It is relevant that these components combine high-strength as well as ductile regions. Until now these components are only produced by modified press hardening operations of steel components. In association with the light-weight concept, a new opportunity to realize tailored components is the use of adapted, high-strength, hardenable aluminum components. During the forming process, the properties of previously solution-annealed components can be adjusted by simultaneous quenching and forming operations. The key influencing factor in quenching and forming operations is the cooling rate. In future, it will be possible to produce property-adapted structural components using high-strength aluminum alloys with the help of different local tool temperatures. Thermally coupled material models are necessary for the simulation of this forming process.

Publications

2024

- , , , :

Ultrasound-assisted material characterization: An innovative method for the non-destructive in-situ detection of microstructural changes of high-strength aluminum alloys

In: Journal of Materials Processing Technology 325 (2024), p. 1-12

ISSN: 0924-0136

DOI: 10.1016/j.jmatprotec.2023.118282

URL: https://www.sciencedirect.com/science/article/pii/S0924013623004272?ssrnid=4598800&dgcid=SSRN_redirect_SD

2023

- , , , , :

Ex-situ and in-situ investigations of the microstructural evolution of AA6082 aluminum alloy during heat treatment

In: Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing (2023), Article No.: 144828

ISSN: 0921-5093

DOI: 10.1016/j.msea.2023.144828

URL: https://www.sciencedirect.com/science/article/abs/pii/S0921509323002526?via=ihub - , , , :

Development of a novel in-situ measurement method for thermo-mechanically coupled material characterization of high-strength aluminum alloys

In: IOP Conference Series: Materials Science and Engineering (2023), p. 012042

ISSN: 1757-8981

DOI: 10.1088/1757-899X/1284/1/012042

2022

- , , :

Effect of elevated tool temperatures on the properties of high-strength aluminum alloys during tailor quench forming (TQF)

In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture Volume 0 (2022), p. 1-10

ISSN: 0954-4054

DOI: 10.1177/09544054221135114