Laser implantation of press hardening tools to influence the tribological and thermal properties for the process application

Head

Researcher

Funding period:

Start: 1. November 2020

Ende: 31. October 2022

Abstract

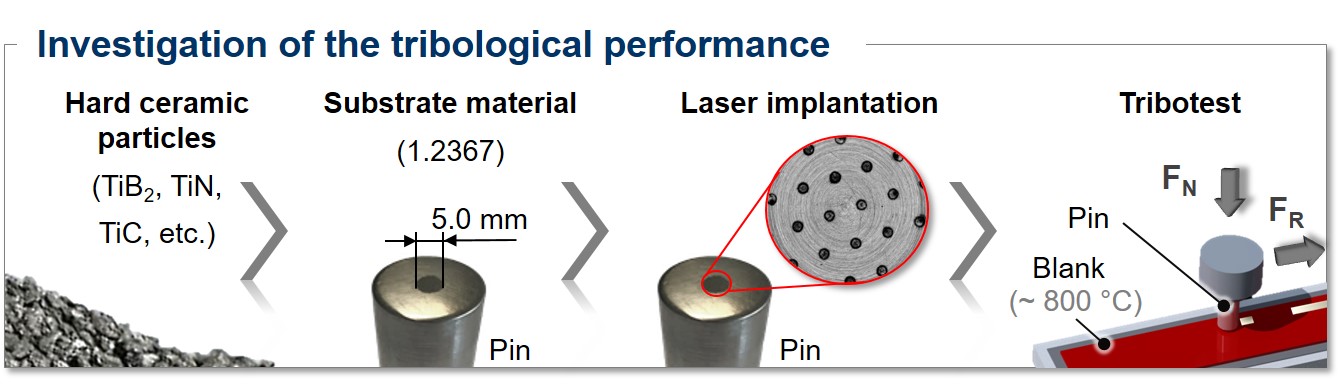

Major development goals of the automotive industry are to increase the passenger safety as well as to reduce the fuel consumption and to achieve emission regulations. Hence, hot stamping has been established as a suitable and resource efficient process to manufacture high-strength and lightweight body-in-white components. However, the production is limited by friction and wear due to high thermo-mechanical tool stresses and the lack of lubricants. The overall aim of this research project is to modify the tool surface by using a laser implantation process in order to influence the thermal, mechanical and tribological interactions in the contact zones. Within the first project phase, tribological highly stressed tool areas as well as requirements for the implant geometry were identified by means of numerical models. Furthermore, suitable hard ceramic particles were determined and their interactions with different laser parameters were analyzed. Tribological experiments have shown that laser-implanted tools exhibit a high wear resistance and decreasing friction forces due to the limitation of the contact area and the reduced chemical affinity between tool and workpiece. By modifying an industry-related tool geometry, it was finally proven that an increased part quality and an improved forming behavior was achieved. However, based on the numerical results, maximum tool loads were located in geometrical complex areas which could not be laser-implanted due to the lack of implantation strategies and the unknown cause-effect relations between the tool and the workpiece. Thus, it is expected that structuring these highly stressed tool areas will significantly improve the tribological behavior. In a second project phase, further investigations with regard to varying tool stresses must be initiated in order to identify the interactions between surface properties, friction and wear behavior. In this context, suitable implants made out of hard phase compositions and tailored structuring patterns will be created for specific load cases. Afterwards, they will be tested in industrially relevant experiments to verify their effectiveness. This approach provides a deeper understanding regarding the interactions between hard ceramic particles and the arrangement of the implants in highly stressed tool areas.

Investigation of the tribological performance by using laser-implanted tool surfaces

Research groups

Publications

2022

- , , , :

Investigation on the thermo-mechanical properties of hot stamped parts by using laser-implanted tool surfaces

The 19th International Conference on Metal Forming 2022 (Taiyuan, 11. September 2022 - 14. September 2022)

In: IOP Conf. Ser.: Mater. Sci. Eng. 1270 012114 2022

DOI: 10.1088/1757-899X/1270/1/012114 - , , , , :

Discontinuous laser dispersing of titanium nitride based hard ceramic particles for improving the tribological behavior of hot stamping tools

8th International Conference on Hot Sheet Metal Forming of High-Performance Steel (Barcelona, 30. May 2022 - 2. June 2022)

In: Oldenburg M, Hardell J, Casellas D (ed.): Hot Sheet Metal Forming of High-Performance Steel 2022

2021

- , , , :

Investigation of the thermal and tribological performance of localized laser dispersed tool surfaces under hot stamping conditions

In: Wear (2021), Article No.: 203694

ISSN: 0043-1648

DOI: 10.1016/j.wear.2021.203694