Improvement of the geometrical accuracy of parts by material flow-optimized coil layouts when extruding functional components

Head

Researcher

Funding period:

Start: 1. April 2022

Ende: 31. March 2024

Abstract

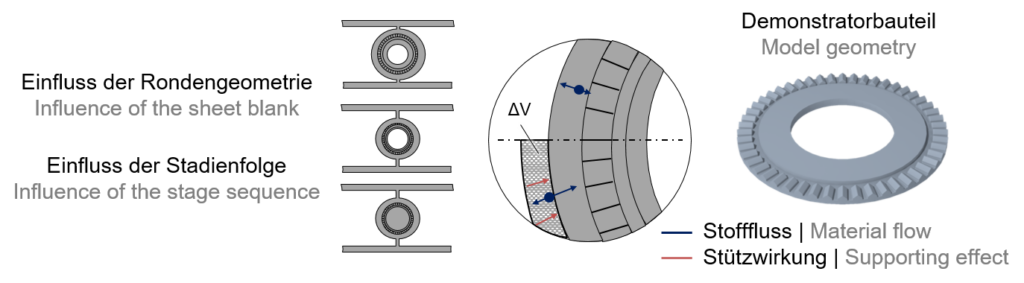

For the production of functionally integrated components made of sheet metal materials, the processes of Sheet-Bulk Metal Forming are suitable, which enable the production of planar components with local functional elements. Limitations in the die filling of the functional elements and high die loads are a result of the demanding forming and process conditions that occur within these processes. When transferring this process class to efficient production from coil, previous investigations also identified anisotropic material flow and anisotropic die loads as relevant process influences when carrying out extrusion processes from sheet coils.

Based on this, the influence of the component design on a multi-stage extrusion process from coil will be analyzed numerically and experimentally within the scope of this research project. In the first step, cause-effect relationships are to be investigated with regard to the local die filling of the functional elements and the local die load when the blank and coil geometry is varied. Furthermore, using these findings, the potential for controlling the material flow and thus improving die filling by adapting the possible stage sequences is to be derived.

Research groups

Publications

2023

- , :

Investigation of the Influence of Slightly Increased Process Temperatures on the Extrusion of Functional Aluminum Components in Sheet-Bulk Metal Forming

Congress of the German Academic Association for Production Technology (Freudenstadt, 20. November 2023 - 23. November 2023)

In: Thomas Bauernhansl, Alexander Verl, Mathias Liewald, Hans-Christian Möhring (ed.): Production at the Leading Edge of Technology, Cham: 2023

DOI: 10.1007/978-3-031-47394-4_65

2022

- , :

Influence of Tailored Surfaces on the Surface Properties of Sheet-Bulk Metal Formed Parts

Steel in Cars and Trucks (SCT) (Milano, 20. June 2022 - 23. June 2022)

In: Proceedings of the Steel in Cars and Trucks (SCT) 2022