Manufacturing of helical-toothed functional components from sheet metal by developing and analyzing a forming process of sheet bulk metal forming

Head

Prof. Dr.-Ing. habil. Marion MerkleinResearcher

Dr. Manuel ReckFunding period:

Start: 1. January 2023

Ende: 31. December 2024

Abstract

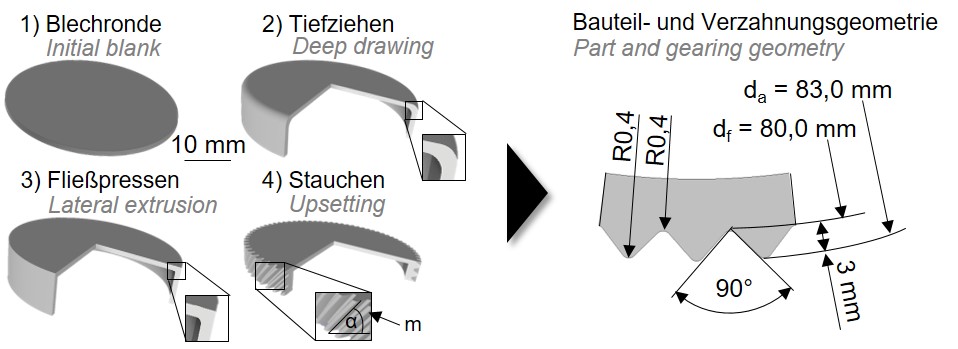

The overarching objective is to determine the basic causal relationships between component and process parameters and to derive causalities in the manufacture of helical components using sheet metal forming. The process-specific challenges, a robust process window and the process limits are to be worked out for a process chain consisting of deep drawing, extrusion and upsetting. In order to enable the industrial use of sheet metal forming for the production of helical components in the medium term, the process must be fundamentally researched and a continuous understanding of the process must be generated from process design to the production of ready-to-use components. In the present project, a parameter-dependent process window with the achievable component properties is to be derived on the basis of an extensive process analysis. Furthermore, the extension of the component functionality that can be realized by forming helical gears with different modules and helix angles on semi-finished sheet metal products by sheet metal forming is fundamentally investigated. A two-stage process chain consisting of deep-drawing/extrusion and upsetting is used as part of the investigations. With the help of a numerical process model, a comprehensive process analysis is carried out and basic causal relationships between the influencing parameters are determined. Based on these findings, the design of the reference process and the experimental implementation are carried out. The simulation model is validated using process and component-specific parameters such as process force, geometry and hardness distribution. Parameter-dependent process limits are identified through the detailed investigation of the influence of the gear geometry and the materials used on the resulting component properties and the tool stress. At the end of the first funding period, a number of sub-goals are being aimed for. Process-specific challenges with regard to the flow paths that can be achieved and the resulting mold filling are identified. In addition, an analysis of the influence of the material flow specific to helical gears on the component properties relevant to use, such as strain hardening and gear quality, is to be carried out. Finally, an adapted process control to avoid subsequent machining is developed